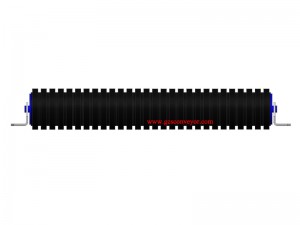

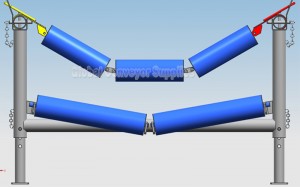

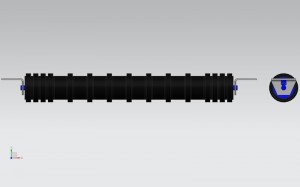

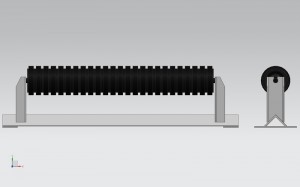

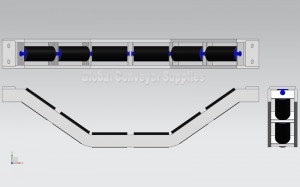

Транспортерски ролер

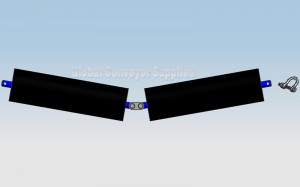

КинаТранспортерски жлеб|Ролерски рамки|Транспортерски системи|Макара|ракување со рефус материјали и ролери за транспортери

Главни карактеристики наGCS ролери на продажба (производи за заштеда на енергија)

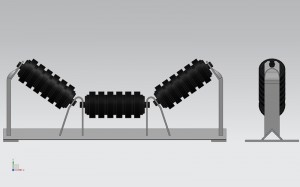

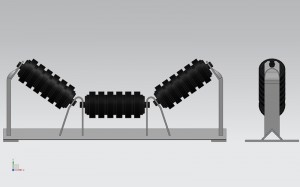

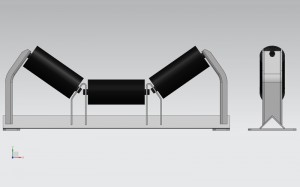

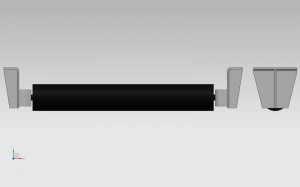

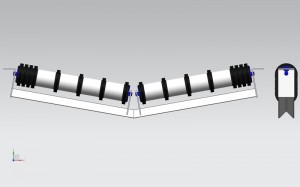

1. Робустна дизајн структура за тешки апликации.

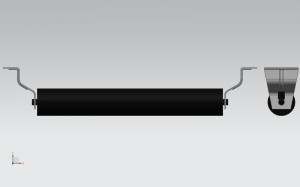

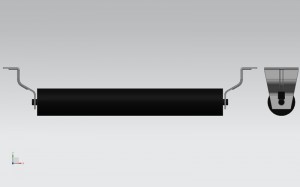

2. Заварувањето на челичната цевка и лежиштето на ролерите се врши со прецизна концентрична автоматска машина за заварување.

3. Сечењето и обработката на челичната цевка и вратилото се врши со CNC автоматска опрема.

4. За да се постигне добро вклопување помеѓу вратилото и лежиштето, крајот на вратилото е прецизно валкан.

5. Монтажата на ролерите се врши со автоматска опрема и ротационата изведба е 100% тестирана.

6. Ролерите и потпорните делови можат да се произведуваат според стандардите DIN/AFNOR/FEM/ASTM/CEMA.

7. Надворешниот штитник е направен од легура со висока цврстина.

8. Континуирано подмачкување и без одржување.

9. Минимум 30.000 часа работен век, подолго во зависност од оптоварувањето.

10. Целосно вакуумско заптивање: внатрешно заптивање, заптивање со 3 жлеба од лавиринт, надворешен гумен прстен во форма на V и центрифугална комора за самочистење.

Уверени сме дека ќе го пронајдете идеалниот избор за вашиот бизнис или организација. Доколку сакате да контактирате со добавувачите на транспортери на GCS во кое било време за да решите проблем или да ви обезбедите помош во продажбата, нашитеконтакт центарсекогаш е достапен да ви помогне.

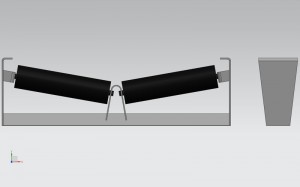

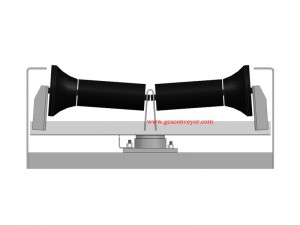

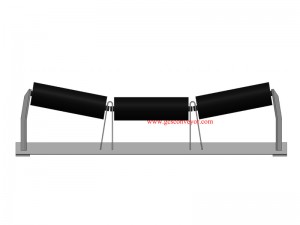

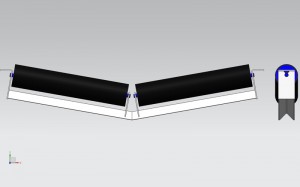

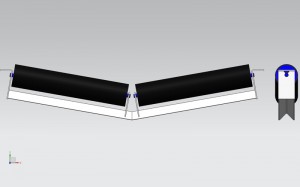

Транспортерски ролерод Кина често се користи за транспорт на алатки, може да ја подобри ефикасноста на преносот, да ги намали трошоците за работна сила и материјални ресурси. Поделена е наРолер за транспортер за тешки услови иЛесен транспортерски ролер. ГКСПрофесионални добавувачи на ролери за транспортери од Кинаможе да ви обезбеди квалитетна услуга, висококвалитетен кинески транспортерски ролер, опрема за транспорт на ленти во Кина и брзо и квалитетно производство.